With the arrival of summer, the high temperature weather has brought no small challenge to the operation of various mechanical equipment, especially for heavy equipment such as crushers. When the crusher works in a high temperature environment, it is prone to various failures, which affect the production efficiency and equipment life. Therefore, it is essential to take effective preventive measures and maintenance strategies. This article will detail how to avoid the failure of the crusher in high temperature weather to ensure the safe and stable operation of the equipment.

First, understand the basic structure and working principle of the crusher

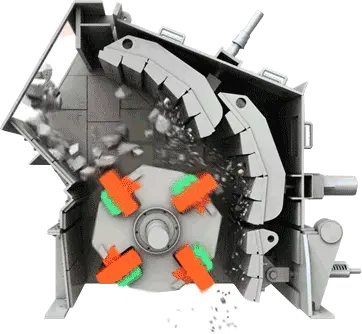

Crusher is mainly composed of frame, crushing chamber, moving jaw plate, static jaw plate, adjusting device, transmission system and so on. The working principle is to squeeze and break the material through the relative movement between the moving jaw plate and the static jaw plate. In the high temperature environment, the lubricant of the crusher is easy to oxidize, the aging of the seal, the failure of the electrical apparatus and other factors may lead to the unstable operation of the equipment.

Second, the crusher is prone to problems in high temperature weather

1. Oil oxidation

In a high temperature environment, the lubricant of the crusher is easy to oxidize, resulting in sludge and carbon deposition, resulting in reduced lubrication performance and increased equipment wear.

2. Aging of seals

High temperature will accelerate the aging of seals, resulting in reduced sealing performance, increased leakage phenomenon, affecting the normal operation of the crusher.

3. Electrical faults

In high temperature weather, electrical equipment is prone to failure, such as insulation performance decline, wire aging, etc., affecting the normal operation of the crusher.

Third, measures to avoid crusher failure

1. Choose the right lubricating oil

In high temperature weather, the lubricating oil with excellent high temperature performance should be selected to ensure the lubrication effect of the crusher. At the same time, it is necessary to check the quality of lubricating oil regularly and replace the deteriorated oil in time.

2. Strengthen the maintenance of seals

Choose high temperature seals, and regularly check their wear, timely replacement of damaged seals. At the same time, the sealing part should be cleaned regularly to keep it clean.

3. Strengthen the inspection and maintenance of electrical equipment

Regular inspection of the crusher‘s electrical equipment, such as motors, controllers, sensors, etc., to ensure its normal operation. At the same time, electrical components suitable for high temperature environment should be selected to prevent failure due to high temperature.

Post time: Apr-10-2025