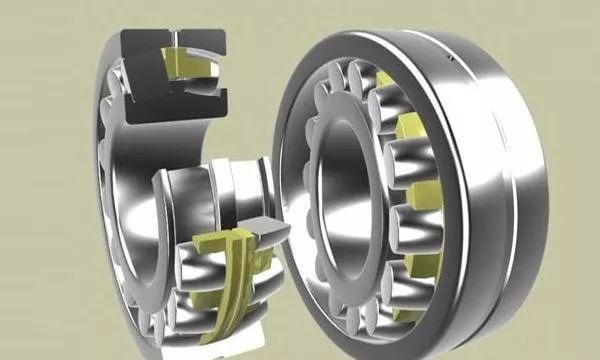

Vibrating screen is a commonly used mining machinery, in which the bearing plays a very important role in the vibrating screen, it is connected to the various parts of the vibrating screen, the friction will be very large, it will inevitably appear a variety of failures, bearing damage will seriously affect the efficiency of the vibrating screen, This article takes you to understand the causes and countermeasures of the shaker bearing lock and the steps for the correct installation of bearings.

First, the common causes of vibration screen bearing lock

1. Poor lubrication, less timely oil injection or oil pipe blockage or lubricating oil deterioration, resulting in bearing lock.

2. Incorrect bearing selection Incorrect bearing installation size or model resulting in failure to operate normally, resulting in bearing lock. 3. Bearing wear and clearance reduction Due to the operation at high temperature, high speed and heavy load, bearing wear and bearing inner ring temperature rise, increase in thermal expansion leads to the reduction of bearing radial working clearance, resulting in bearing lock.

Second, the vibration screen bearing holding measures

1. Add lubricating oil in time to keep the tubing unobstructed, and use lubricating oil within the shelf life.

2. Select bearings that match the type and mounting size of the equipment.

3. Check the bearing wear regularly and replace the bearing if necessary.

Three, the correct installation of the vibrating screen bearing steps

1. Clean the bearing and the associated part of the bearing to keep it clean.

2. Check the size of the associated parts and the accuracy of the processing.

3. Install and check.

(1) Cylindrical hole vibrating screen bearing installation

Method 1: Press into, this is the method used for small bearings, is to pad the pad into the inner ring, and then press the bearing into the inner ring to the shaft shoulder.

Method 2: hot loading, this is the method used for large bearings, hot loading method is to put the bearing in the oil after heating expansion so as to easily install on the shaft, this method not only takes a short time and does not have any external force on the bearing.

(2) Cone hole vibrating screen bearing installation

Method 1: Fix the inner ring directly on the cone shaft.

Method 2: Install the bearing on the cylindrical shaft with the fastening sleeve and disassembling sleeve.

4. Add lubricating oil. The method of adding lubricating oil to different bearings is different. General bearings, without cleaning directly added; Instrument bearings and high speed bearings, wash the anti-rust agent on the bearing with clean oil first, and then add lubricating oil; Add lubricating oil to the bearing, no need to add lubricating oil.

Brief summary

Bearing failure often causes serious consequences, regular maintenance and overhaul is an important means to extend the service life of the machine and ensure normal work, we should pay attention to.

Post time: Jan-13-2025